- POSITRON

- TELELITE_HVI

TeleLite HVI unités préconfigurées

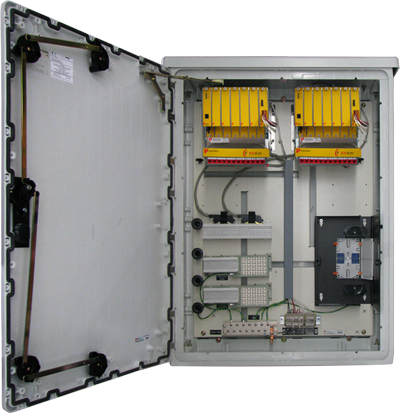

Positron takes pride in manufacturing turnkey TeleLite High Voltage Interface (HVI) Assemblies that provide the best isolation.

Our HVI Assemblies are built on a manufacturing line. Every unit is thoroughly tested to insure that the field installation is without a hitch. Personnel safety and equipment reliability was foremost in the engineering design of this turnkey assembly.

Positron’s HVI solutions include a full portfolio of products that cost-effectively meet your requirements. TeleLite supports an extensive range of service types providing customers with a flexible, cost-effective, robust and reliable fiber optic isolator solution.

The TeleLite HVI product numbering simplifies the ordering process and reduces deployment costs.

Benefits

- Easier to build standard configurations that may be used across an organization. Using pre-configured HVI solutions ensures consistency between projects and installations, accelerating field staff’s knowledge and effectiveness at servicing the TeleLite installations.

- Faster to configure and order, thus reducing engineering costs.

- Simplified equipment selection significantly reduces ordering errors and time delays in executing mission critical isolation projects.

Simplified Four Step Ordering Process

Step 1 Choose a CABINET ENCLOSURE OPTION (CO Site [CFJ] and Station Site [OEI]) as well as a mounting option. All our enclosures are based on NEMA-4x compliant packages and are available in polymer or aluminum. For NEBS Level 3 compliant outdoor installations, the 40” x 30” aluminum enclosure is required. For indoor installations, the enclosure is optional.

Step 2Choose a BACKBOARD OPTION (CO Site [CFJ] and Station Site [OEI]). The backboard configurations are pre-engineered and pre-wired for fast and efficient planning and installation by field staff.

Step 3 Select a POWERING OPTION.

Step 4 Select the appropriate plug-in cards for the circuit types required for the project (refer to TeleLite Optical Isolation section).

Note:

When ordering a Cabinet Configuration: an option from 1, 2 and 3 must be selected.

When ordering a Backboard Configuration: an option from 2 and 3 must be selected.

Positron’s TeleLite solution has been tested and is fully compliant to NEBS Level 3 requirements in addition to FCC-15, FCC-68 and CSA/UL ensuring a robust and reliable system solution for your critical communication needs.

-

Vérificateur d’isolateurs en porcelaine

-

Vérificateur d’isolateurs en composite

-

Vérificateur pour centrale électrique

-

Tablette portable

-

Blocs d'alimentation

-

Isolateurs à base de fibre optique TeleLite

-

Boîtiers multi-cartes

-

Cartes de distribuition

- POTS

- T1

- 2W/4W AC data

- 56K DDS

- ETHERNET

- OPX

- DID

-

- Unités préconfigurées HVI TeleLite

- Assemblage TeleLite CFJ/OEI

-

724201-05 Assemblage de panneau 27” x 21”

724201-05 Assemblage de panneau 27” x 21”

724201-15 Assemblage de boîtier 32” x 24”

724201-15 Assemblage de boîtier 32” x 24”

724211-05 Assemblage de panneau 37” x 29”

724211-05 Assemblage de panneau 37” x 29”

724211-15 Assemblage de boîtier 40” x 32”

724211-15 Assemblage de boîtier 40” x 32”

724221-05 Assemblage de panneau 37” x 29” 2 shelves

724221-05 Assemblage de panneau 37” x 29” 2 shelves

724221-15 Assemblage de boîtier 40” x 32” 2 shelves

724221-15 Assemblage de boîtier 40” x 32” 2 shelves

722201-05 Assemblage de panneau 17.5”H x 15.5”W

722201-05 Assemblage de panneau 17.5”H x 15.5”W

722201-15 Assemblage de boîtier 18”H x 16”W x 10”D 1 shelf

722201-15 Assemblage de boîtier 18”H x 16”W x 10”D 1 shelf

722301-05 Assemblage de panneau 17.5”H x 15.5”W

722301-05 Assemblage de panneau 17.5”H x 15.5”W

722301-15 Assemblage de boîtier 18”H x 16”W x 10”D

722301-15 Assemblage de boîtier 18”H x 16”W x 10”D

7232BS-10 Panneau 30"x20"

7232BS-10 Panneau 30"x20"

7243BS-10 Panneau 40"x30"

7243BS-10 Panneau 40"x30"

7243BD-10 Panneau double 40"x30"

7243BD-10 Panneau double 40"x30"

7243BD-22 Panneau double 40"x30"

7243BD-22 Panneau double 40"x30"

7232PC-PL/WL Boîtier en polymère 30"x20"

7232PC-PL/WL Boîtier en polymère 30"x20"

7243PC-PL/WL Boîtier en polymère 40"x30"

7243PC-PL/WL Boîtier en polymère 40"x30"

7243NC-PL/WL Boîtier 40"x30"

7243NC-PL/WL Boîtier 40"x30"

-

- Assemblage TeleLite ZOI CFJ

- TeleLite Piédestaux

- TeleLite ZOI Piédestaux

- Accessoires TeleLite

-

Isolation d'haute tension

-

Boîtiers multi-cartes

-

Bloque d'alimentation

-

750004 Châssis d'alimentation universel

750004 Châssis d'alimentation universel

751312 Carte de batterie de résérve

751312 Carte de batterie de résérve

751313MC Carte de batterie de résérve de 120Vac / -24dc ou -129Vdc / -24Vdc

751313MC Carte de batterie de résérve de 120Vac / -24dc ou -129Vdc / -24Vdc

751316 Carte de batterie de résérve -48 Vdc/-24 Vdc

751316 Carte de batterie de résérve -48 Vdc/-24 Vdc

751318MC Carte de batterie de résérve de 120Vac / 129Vdc to -48Vdc Sortie

751318MC Carte de batterie de résérve de 120Vac / 129Vdc to -48Vdc Sortie

751319MC Carte de batterie de résérve flottant 48Vdc Input to -48Vdc Sortie

751319MC Carte de batterie de résérve flottant 48Vdc Input to -48Vdc Sortie

751324 Carte de batterie de résérve de batterie 24 Vdc/-24 Vdc

751324 Carte de batterie de résérve de batterie 24 Vdc/-24 Vdc

-

- POTS

- T1

- HDSL

- ADSL2+

- AC Data

- OPX

- ADTRAN Total Reach

- Boîtiers autonomes

-

-

Unités préconfigurées HVI Teleline

-

Configurations de 3 cartes

-

Configurations de 5 cartes

- Configurations de 8 cartes

-

751950-05 Panneau HVI avec 8 cartes

751950-05 Panneau HVI avec 8 cartes

751950-05CU6 Panneau HVI avec 8 cartes, 2 boîtiers d'alimentation NIU

751950-05CU6 Panneau HVI avec 8 cartes, 2 boîtiers d'alimentation NIU

751950-15 Boîtier HVI avec 8 cartes

751950-15 Boîtier HVI avec 8 cartes

751950-15CU6 Boîtier HVI avec 8 cartes, 2 boîtiers d'alimentation NIU

751950-15CU6 Boîtier HVI avec 8 cartes, 2 boîtiers d'alimentation NIU

751956-05 Panneau HVI avec deux boîtiers de 8 cartes

751956-05 Panneau HVI avec deux boîtiers de 8 cartes

751956-15 Boîtier HVI avec deux boîtiers de 8 cartes

751956-15 Boîtier HVI avec deux boîtiers de 8 cartes

-

-

-

Accessoires Teleline

-

Accessoires HVI

-

Parafoudres

- Réacteurs de Drainage Mutuel

- Autres

-

3781301P/50, 3781301P/60

3781301P/50, 3781301P/60 378209C1/50, 378209C1/60

378209C1/50, 378209C1/60

378325 tablette

378325 tablette 725610 unité de voltage à la sortie

725610 unité de voltage à la sortie 725611 unité de voltage d’entré

725611 unité de voltage d’entré